CARPENTRY

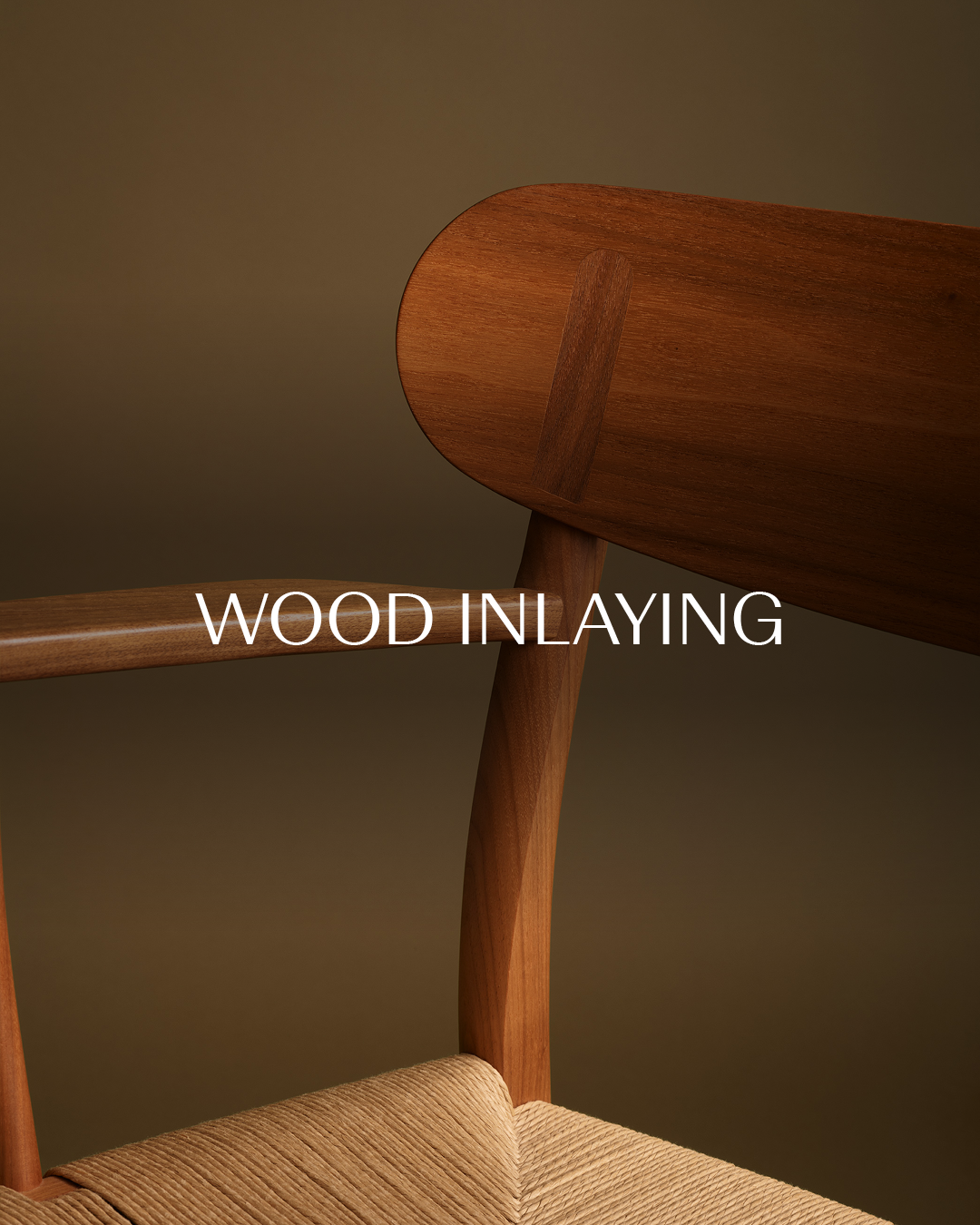

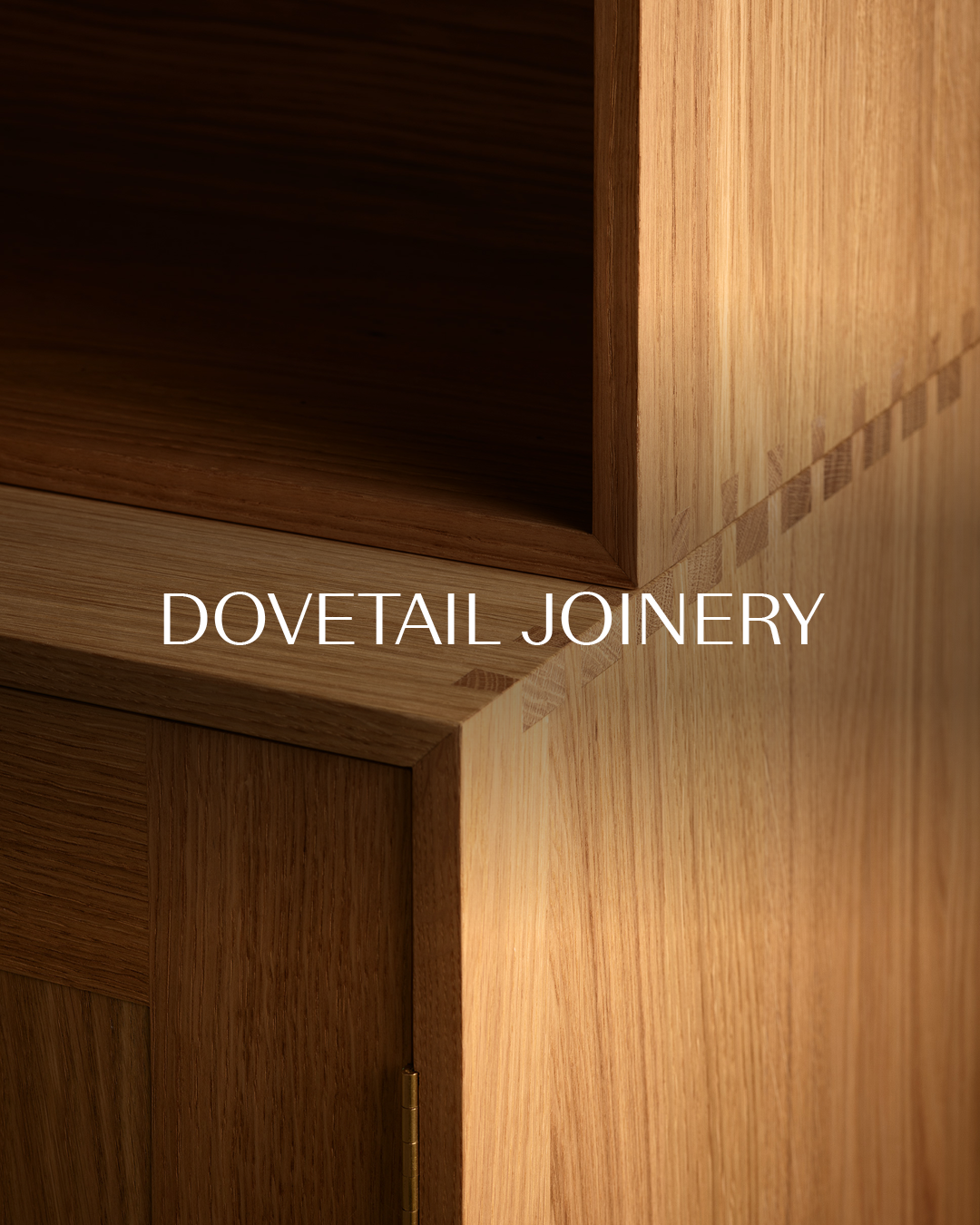

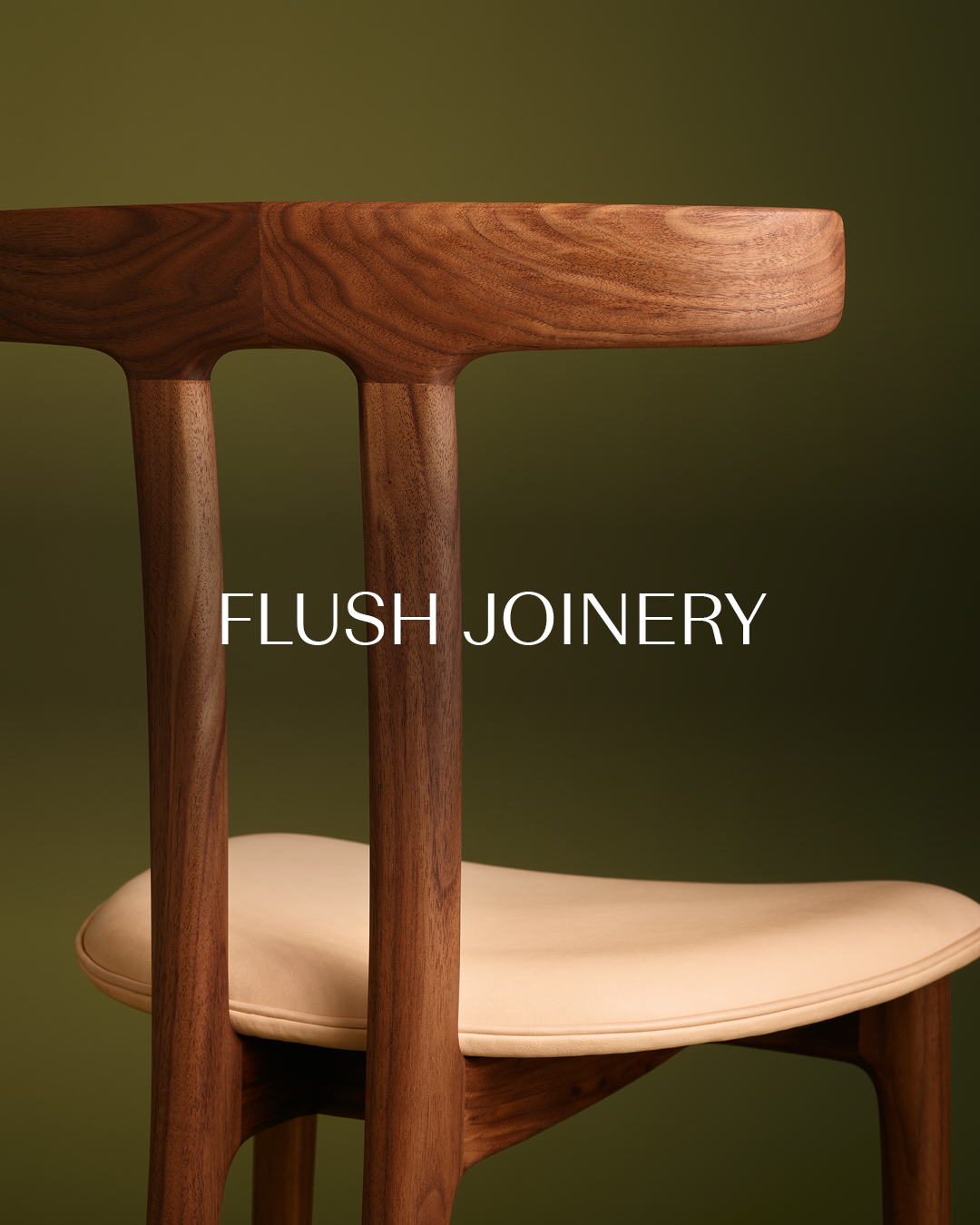

Nordic woodworking can be traced back to the Bronze Age. These simple log structures evolved into the Viking’s impressive wooden longships. In the 17th century, Nordic settlers used their expert carpentry skills to build the early European colonies in the US. Every Carl Hansen & Søn piece is meticulously finished using traditional carpentry techniques that represent the best of Danish furniture-making’s long lineage, from century-old cabinetmaker joinery, to woodturning on a lathe. While these techniques serve a purpose, some designers decide to be decorative with them. Many of Hans J. Wegner’s chairs incorporated an elegant cruciform cover cap on the backrest that provided an ornamental solution to hiding the sight of screws. And Børge Mogensen often chose to accentuate the joints on his pieces in contrasting wood. Even the smallest detail, they proved, could be beautiful.

Many carpentry hours were spent on Ole Wanscher’s T-Chair, which requires smooth transitions in the joints to achieve its light expression. To create the century-old joinery used in most of our pieces, a CNC machine is used to cut the wood, providing the necessary precision to create a perfect fit. Then, it is polished, sanded, and glued by hand, with expert tweaks to ensure a seamless joint.

First unveiled in 1963, Hans J. Wegner’s CH07 Shell Chair was too avant-garde for the general public. Made from moulded plywood, the wing-like seat and curved backrest are created from multiple veneer layers that are glued together through heat and pressure. When Carl Hansen & Søn reintroduced it 36 years later, the strength, lightness, and comfort achieved by its plywood moulding made it immensely popular with a new generation.